Celebrating 20 Years of Service Excellence

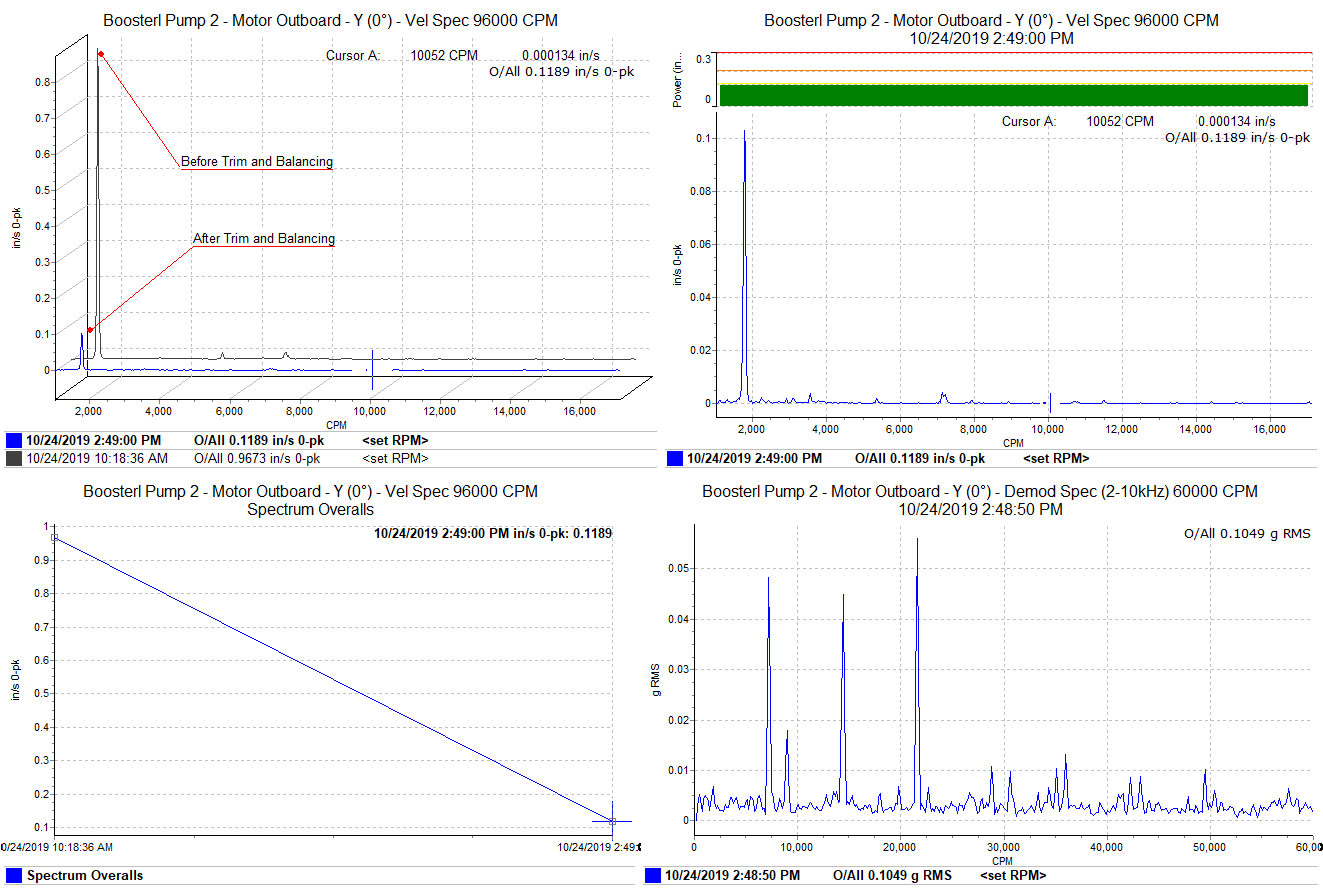

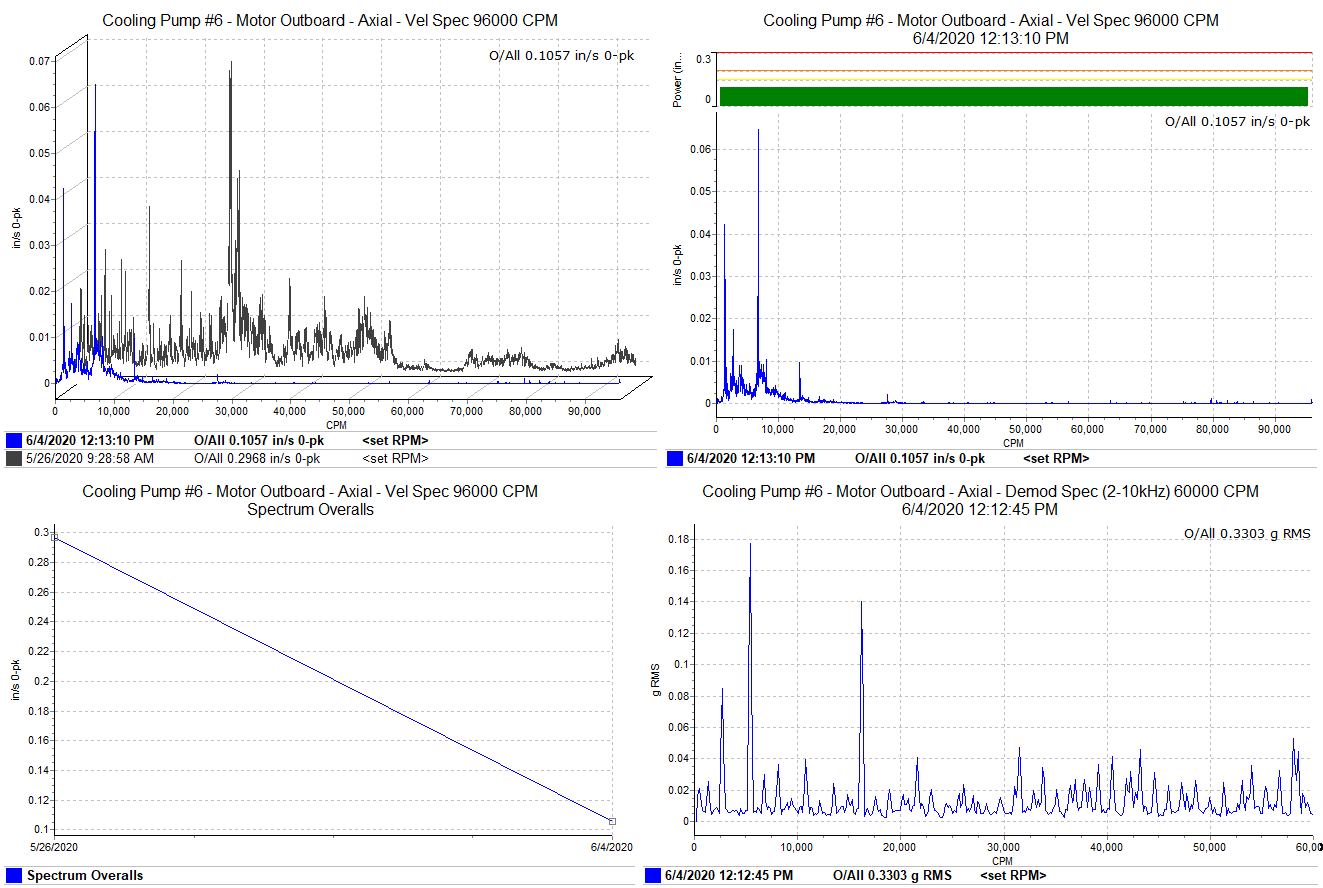

Monitoring vibration is important because it measures rotating equipment’s mechanical well-being as well as its reliability. Vibration is either the result of an unbalanced condition in a component/assembly or misalignment. And in some cases, it may be both. Vibration in excess can and often does reduce the mean time between failure on equipment, and may cause a Mechanical Seal to leak. Therefore, vibration analysis is a critical part of preventative maintenance.

Advanced Pump Repair Service Inc. is fully equipped to provide vibration testing. This includes bearing, cavitation/recirculation, misalignment and resonance, using industry standard vibration analysis equipment and advanced testing equipment to troubleshoot and minimize all equipment failures.

APR can visit your facility, and our trained technician will conduct a vibration analysis. The analysis will determine the frequency, which will help narrow down the possible cause of the vibration. A copy of an easy-to-understand vibration analysis report will be supplied to the customer, along with a recommended plan to reduce the vibration problem with acceptable limits. This will help the customer decide if more work or attention to their equipment is necessary.

We can carry out the recommended plan to reduce the vibration to acceptable limits, if the customer wishes. In most cases, laser alignment will be implemented first, then pipe strain and system piping vibration are considered, along with component imbalance within the rotating assembly.

APR backs all testing and workmanship 100%, according to industry standards.